The Innovative Power of Industrial Scouring Pads: Non-woven Fabric and Composite Materials

The application of non-woven fabric and composite materials is profoundly transforming the performance and user experience of industrial scouring pads, making them an indispensable innovative force in the modern industrial cleaning sector. The following points illustrate how they shape the versatility, high-efficiency cleaning, and eco-friendly attributes of industrial scouring pads:

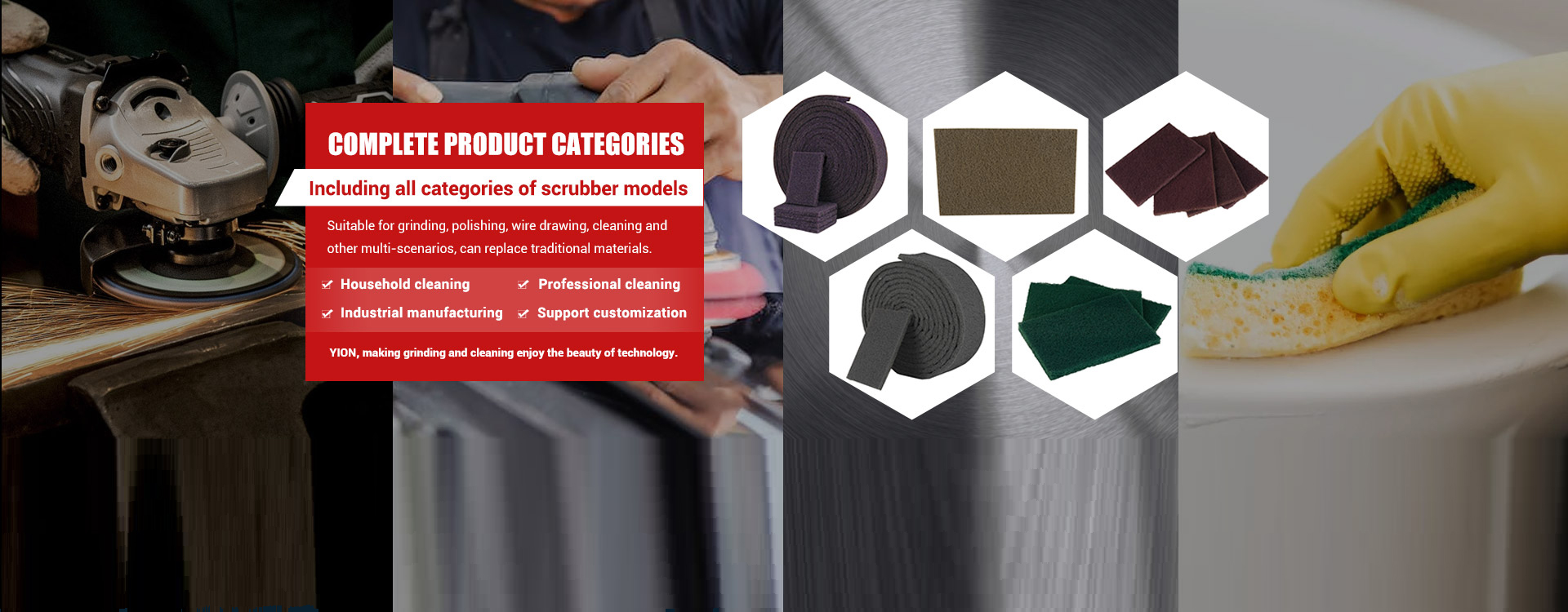

Integration of Multiple Functions: Non-woven fabric and composite materials endow industrial scouring pads with "one pad, multiple functions." The non-woven fabric layer provides excellent wiping power and water absorption, while composite materials such as abrasive particles, sponge, and activated carbon target different industrial stains for specialized cleaning. For instance, a composite abrasive surface can remove oxide layers from metal surfaces, while a composite sponge absorbs oil and dust, achieving deep cleaning.

Outstanding Cleaning Efficiency: Composite materials optimize the cleaning efficiency of industrial scouring pads. The three-dimensional structure of non-woven fabric enhances its ability to capture and remove dirt, while composite hard abrasives or highly efficient adsorbent materials accelerate the stripping and absorption of stubborn stains. Some products even feature self-cleaning capabilities, such as scouring pads containing activated carbon that can adsorb and decompose odors, improving the quality of the working environment.

Robust Durability: The high strength and stability of non-woven fabric, combined with the wear-resistant properties of composite materials, enable industrial scouring pads to maintain their shape and extend their service life when facing high-intensity, high-frequency cleaning tasks. Some products also undergo treatments such as anti-static, mold-resistant, and high-temperature resistance to meet the requirements of complex industrial environments.

Eco-friendly and Sustainable: Industrial scouring pads made from non-woven fabric and composite materials actively respond to environmental trends. Non-woven fabric raw materials often originate from renewable resources, and waste is easy to recycle and dispose of. Composite biodegradable materials or reusable designs, such as replaceable non-woven fabric sheets, further reduce waste generation and lower environmental impact.

Customized Services: Based on the flexibility of non-woven fabric and composite materials, manufacturers can customize parameters such as material combination, thickness, hardness, and size according to specific industrial cleaning needs, providing personalized solutions. This high degree of customization enables industrial scouring pads to better meet the unique cleaning challenges of various industries, enhancing cleaning effectiveness and economic benefits.

The innovative integration of non-woven fabric and composite materials has enabled industrial scouring pads to achieve functional diversification, environmental sustainability, and high customization while maintaining high-efficiency cleaning performance. This has brought revolutionary changes to modern industrial cleaning and has become a significant force driving the advancement of industrial cleaning technology.

Key Considerations for Selecti

Key Considerations for Selecti

The Innovative Power of Indust

The Innovative Power of Indust

The scouring pad is a represen

The scouring pad is a represen

Analysis of the Efficient Appl

Analysis of the Efficient Appl