What is an industrial scouring pad?

An industrial scouring pad is a high-efficiency wiping tool specifically designed for industrial cleaning, polishing, deburring, and other applications. It is widely used in various manufacturing, repair, maintenance, and cleaning operations. Its main characteristics and applications are as follows:

Material and Structure: Industrial scouring pads are typically made from high-strength fibers such as nylon and polyester, formed into an open mesh structure through special weaving or bonding processes. This structure grants the pads excellent wear resistance, elasticity, and water absorbency. Some products may also incorporate abrasive particles (such as alumina or silicon carbide) to enhance their ability to remove dirt, rust, and for polishing and grinding.

Types and Grades: Industrial scouring pads are available in different types and grades according to usage requirements. For instance, coarse-grit pads are suitable for treating heavily rusted or rough surfaces, while fine-grit pads are used for fine polishing or removing minor blemishes. Additionally, non-abrasive (also known as non-grit) pads are primarily used for cleaning, degreasing, and defatting tasks that do not require abrasion.

Application Areas: Industrial scouring pads find extensive use across numerous industries, including but not limited to:

Metalworking: Removing rust, deburring, and polishing metal components to improve surface quality.

Automotive Repair: Cleaning oil, rust, and polishing paint surfaces on engines, chassis, and other parts.

Architectural Decoration: Cleaning and polishing building materials such as stone, tiles, and glass to enhance surface smoothness and gloss.

Electronics Manufacturing: Cleaning circuit boards and precision components to remove solder residues.

Food Processing: Efficiently cleaning kitchen equipment and work surfaces to meet food safety standards.

Usage Methods and Precautions:

Industrial scouring pads can be used both dry and wet. For better results, they can be used in conjunction with cleaning agents, polishing compounds, or other chemical preparations as needed.

For abrasive scouring pads, the appropriate grit size should be selected based on the hardness and roughness of the surface to be treated to avoid excessive wear or ineffective results.

The pads should be replaced or flipped over in a timely manner during use to ensure effective cleaning or polishing. Pads that are severely worn or have lost their cleaning ability should be discarded promptly to prevent scratching workpieces or affecting work efficiency.

After use, the pads should be stored properly to avoid moisture and mildew, maintaining their good performance.

With their excellent durability, versatility, and efficient cleaning and polishing capabilities, industrial scouring pads have become an indispensable auxiliary tool in modern industrial production, maintenance, and repair operations.

Where are industrial scouring

Where are industrial scouring

What is an industrial scouring

What is an industrial scouring

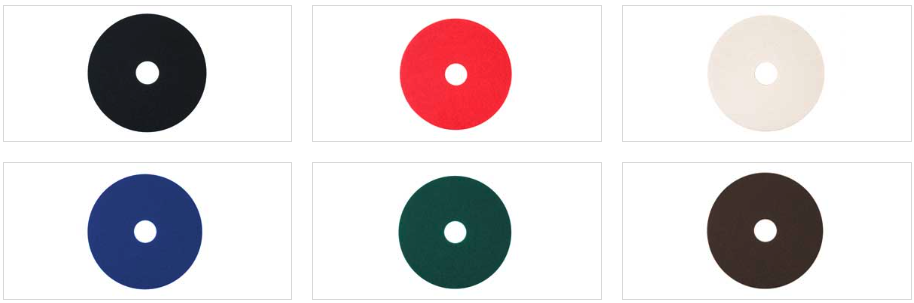

Color Classification and Uses

Color Classification and Uses

The Private Labeling Cooperati

The Private Labeling Cooperati