Where are industrial scouring pads used?

Industrial scouring pads are widely used across multiple industrial sectors, including metalworking, woodworking, automotive repair, architectural decoration, electronics manufacturing, food processing, and the general cleaning and maintenance of industrial equipment. They play a crucial role in enhancing product quality, ensuring production efficiency, and maintaining equipment performance.

The primary applications of industrial scouring pads are as follows:

Metalworking Industry:

Surface Treatment: Used for derusting, descaling, deburring, grinding, and polishing metal products such as machinery, automotive components, and hardware to improve surface quality and corrosion resistance.

Pre-Coating Treatment: Cleans and roughens metal surfaces before painting to enhance adhesion between the coating and substrate, ensuring optimal coating performance and longevity.

Woodworking and Furniture Manufacturing:

Wood Polishing: Used for sanding and polishing wooden furniture, floors, doors, and windows to eliminate processing marks and enhance surface smoothness and gloss.

Coating Preparation: Cleans and textures wood surfaces before coating to facilitate uniform paint adhesion and improve decorative effects.

Automotive Repair and Maintenance:

Bodywork Restoration: Used to remove old paint, rust, and scratches before automotive touch-up painting, as well as for initial polishing of new paint surfaces.

Engine and Component Cleaning: Removes oil, dirt, and rust from engines, brake systems, chassis, and other components for thorough cleaning and maintenance.

Architectural Decoration Industry:

Stone and Tile Treatment: Used for cleaning, grinding, and polishing marble, granite, tiles, and other building materials to improve flatness and gloss.

Glass Cleaning: Efficiently removes dust, stains, and adhesive residues from architectural glass, particularly suitable for large-scale curtain walls and windows.

Electronics Manufacturing and Precision Instrument Industry:

Circuit Board Cleaning: Used to remove solder residues, dust, and grease from circuit boards and electronic components during assembly or repair to ensure reliable electrical connections.

Precision Component Processing: Used for fine polishing and decontamination of precision mechanical parts and optical lenses to guarantee surface accuracy and cleanliness.

Food Processing and Catering Industry:

Kitchen Equipment Cleaning: Used to clean ovens, stoves, cutting boards, utensils, and other kitchen facilities and equipment, effectively removing oil, food residues, and meeting food safety and hygiene standards.

Other Applications:

Plastic and Rubber Product Surface Treatment: Used for deburring and polishing plastic molds, rubber products, etc., to enhance product quality.

General Industrial Equipment Maintenance: Used for regular cleaning and derusting of production equipment, pipelines, workbenches, etc., to maintain optimal equipment operation.

Exploration of the Diverse Mat

Exploration of the Diverse Mat

Where are industrial scouring

Where are industrial scouring

What is an industrial scouring

What is an industrial scouring

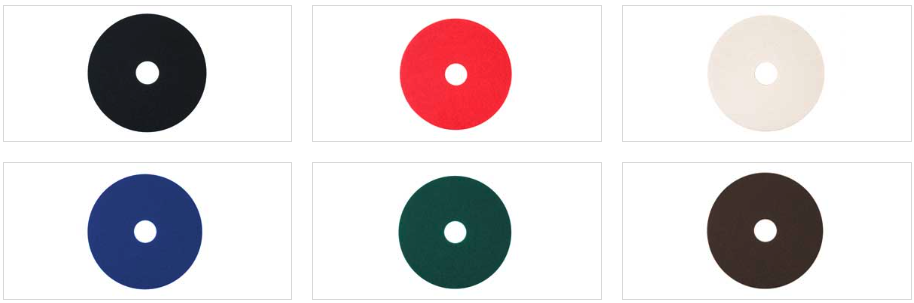

Color Classification and Uses

Color Classification and Uses