The material selection and structural characteristics of scouring pads

Scouring pads are multifunctional cleaning tools designed with material and structural features aimed at providing efficient cleaning, rust removal, polishing, and other functions, while ensuring durability and adaptability. Below is an overview of the material and structural characteristics of scouring pads:

Material Selection:

Fibrous Materials: The main body of scouring pads is typically made from high-strength synthetic fibers, such as nylon and polyester. These fibers possess excellent wear resistance, tensile strength, and chemical corrosion resistance, ensuring that the scouring pads maintain good cleaning efficiency and physical stability over prolonged use.

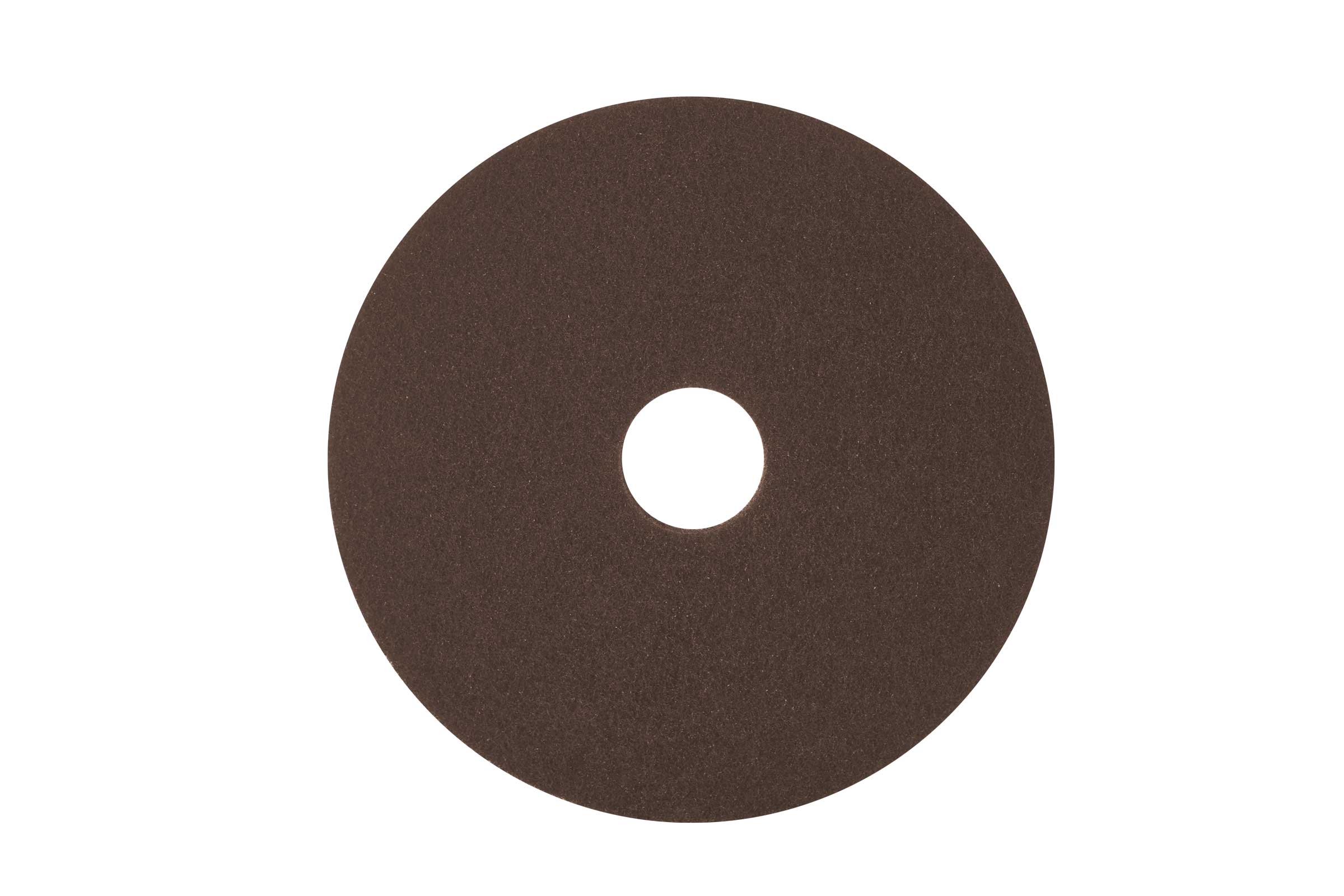

Abrasive Particles (if applicable): Some scouring pad products incorporate abrasive particles, such as aluminum oxide and silicon carbide, to enhance their ability to remove rust, scale, or perform fine polishing on metal surfaces. These particles are evenly distributed among the fibers, providing the necessary physical abrasion.

Structural Design:

Open Mesh Structure: Scouring pads adopt a special weaving or bonding process to form an open mesh structure. This structure allows for numerous tiny gaps between the fibers, resulting in good adsorption and permeability. It can penetrate into the nooks and crannies of object surfaces, effectively adsorbing and removing stains, rust, and burrs.

Fiber Arrangement and Density: The fibers in scouring pads are tightly arranged in various directions, forming a dense yet flexible contact surface. This ensures comprehensive coverage and effective removal of various stains during the wiping process. Different types of scouring pads may have varying fiber densities and arrangements to suit different cleaning and polishing needs.

Double-Sided or Single-Sided Design: Some scouring pad products are designed for double-sided use. One side may contain abrasive particles for rust removal or polishing, while the other side is non-abrasive or fine-grained for regular cleaning or fine polishing. Single-sided scouring pads, on the other hand, focus on a specific function, such as heavy-duty rust removal or fine polishing.

Comprehensive Characteristics:

The materials and structures of scouring pads collectively determine their efficient cleaning, rust removal, and polishing performance, as well as their good durability and adaptability. The fibrous materials endow them with wear resistance, tensile strength, and chemical corrosion resistance, while the open mesh structure ensures outstanding adsorption and permeability. The presence of abrasive particles grants scouring pads physical abrasion capabilities, making them suitable for metal surface treatment. The differences in structural design enable scouring pads to adapt to various cleaning tasks, with coarse-grained types suitable for heavy-duty cleaning and fine-grained or non-abrasive types for fine polishing or protecting sensitive surfaces.

The materials and structures of scouring pads are meticulously designed to provide an efficient, durable, and highly adaptable cleaning tool suitable for cleaning, rust removal, and polishing operations across multiple fields, including households, industries, automobiles, and construction.

Scouring pads are multifunctio

Scouring pads are multifunctio

The material selection and str

The material selection and str

Diverse materials of industria

Diverse materials of industria

Exploration of the Diverse Mat

Exploration of the Diverse Mat