Exploration of the Diverse Materials and Performance Characteristics of Industrial Scouring Pads

As a crucial cleaning tool in modern industrial production and maintenance, the choice of materials for industrial scouring pads directly determines their performance and scope of application. This article will provide a detailed introduction to several major materials used in industrial scouring pads and their corresponding performance characteristics, enabling users to select the most suitable scouring pad products according to their actual needs.

I. Nylon Material

Nylon is one of the most common fiber materials in industrial scouring pads, renowned for its high strength, wear resistance, tensile resistance, and good chemical stability. Its main characteristics include:

- Durability: Nylon fibers possess high strength and are not prone to breaking. They can maintain good structural integrity even under repeated wiping and strong friction, thereby extending the service life.

- Corrosion Resistance: Nylon exhibits good resistance to acids, alkalis, and other chemicals, making it suitable for use in various industrial cleaners or corrosive environments.

- Water Absorbency: Nylon fibers have moderate water absorbency, enabling them to effectively adsorb and carry cleaning solutions, thus improving cleaning efficiency.

II. Polyester Fiber

Polyester fiber (PET) is applied in industrial scouring pads due to its excellent wear resistance, heat resistance, and low shrinkage. Its characteristics include:

- High Temperature Resistance: Polyester fiber has superior heat resistance compared to nylon, allowing it to maintain stable performance at higher temperatures. It is suitable for high-temperature operating environments or occasions requiring hot water cleaning.

- Stain Resistance: The smooth surface of polyester fiber makes it less prone to adsorbing oil stains, facilitating easy cleaning and maintaining the cleanliness of the scouring pad itself.

- Wrinkle Resistance: Polyester fiber has good wrinkle resistance. After multiple uses and washings, the scouring pad retains its shape well, without affecting its usage effectiveness.

III. Metal Fiber

Metal fiber scouring pads, such as those made of stainless steel fiber or copper fiber, possess the following characteristics:

- High Strength: Metal fibers have significantly higher strength than ordinary synthetic fibers, making them particularly suitable for heavy-duty industrial cleaning and polishing.

- Electrical Conductivity: Metal fiber scouring pads possess electrical conductivity, making them suitable for antistatic cleaning in electronic equipment, semiconductor devices, and other applications.

- Corrosion Resistance: Metal fiber scouring pads have good tolerance to most chemicals, making them suitable for use in corrosive environments.

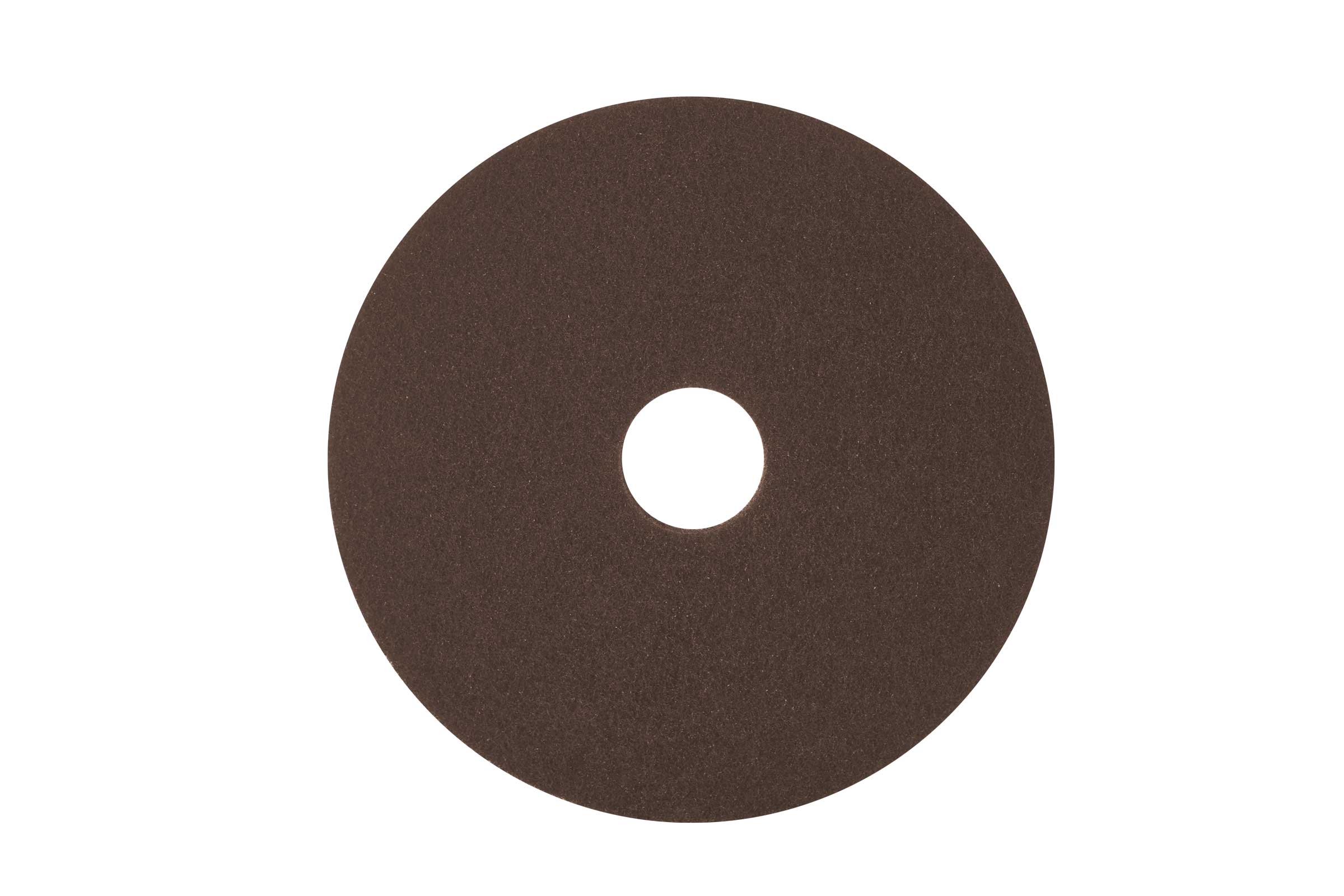

IV. Non-woven Fabric and Composite Materials

Non-woven fabric scouring pads are formed by bonding fibers arranged in a directional or random manner through mechanical, thermal bonding, or chemical methods. They have the following characteristics:

- Structural Diversity: The structure of non-woven fabric can be adjusted according to needs, such as open, closed, or hybrid types, to adapt to different cleaning and polishing requirements.

- Strong Liquid Absorbency: Non-woven fabric scouring pads have good liquid absorption and retention capabilities, enabling them to effectively carry and release cleaning agents.

- Composite Functions: Additional functions can be imparted to non-woven fabric scouring pads by incorporating additives such as abrasive particles, antibacterial agents, and antistatic agents.

Diverse materials of industria

Diverse materials of industria

Exploration of the Diverse Mat

Exploration of the Diverse Mat

Where are industrial scouring

Where are industrial scouring

What is an industrial scouring

What is an industrial scouring