How to Choose the Material of Sponge Pads?

Selecting the appropriate sponge pad material is crucial for improving cleaning efficiency and protecting the surfaces being cleaned. Here are several important factors to consider when choosing the material of sponge pads:

1. Choose based on the material of the cleaning object

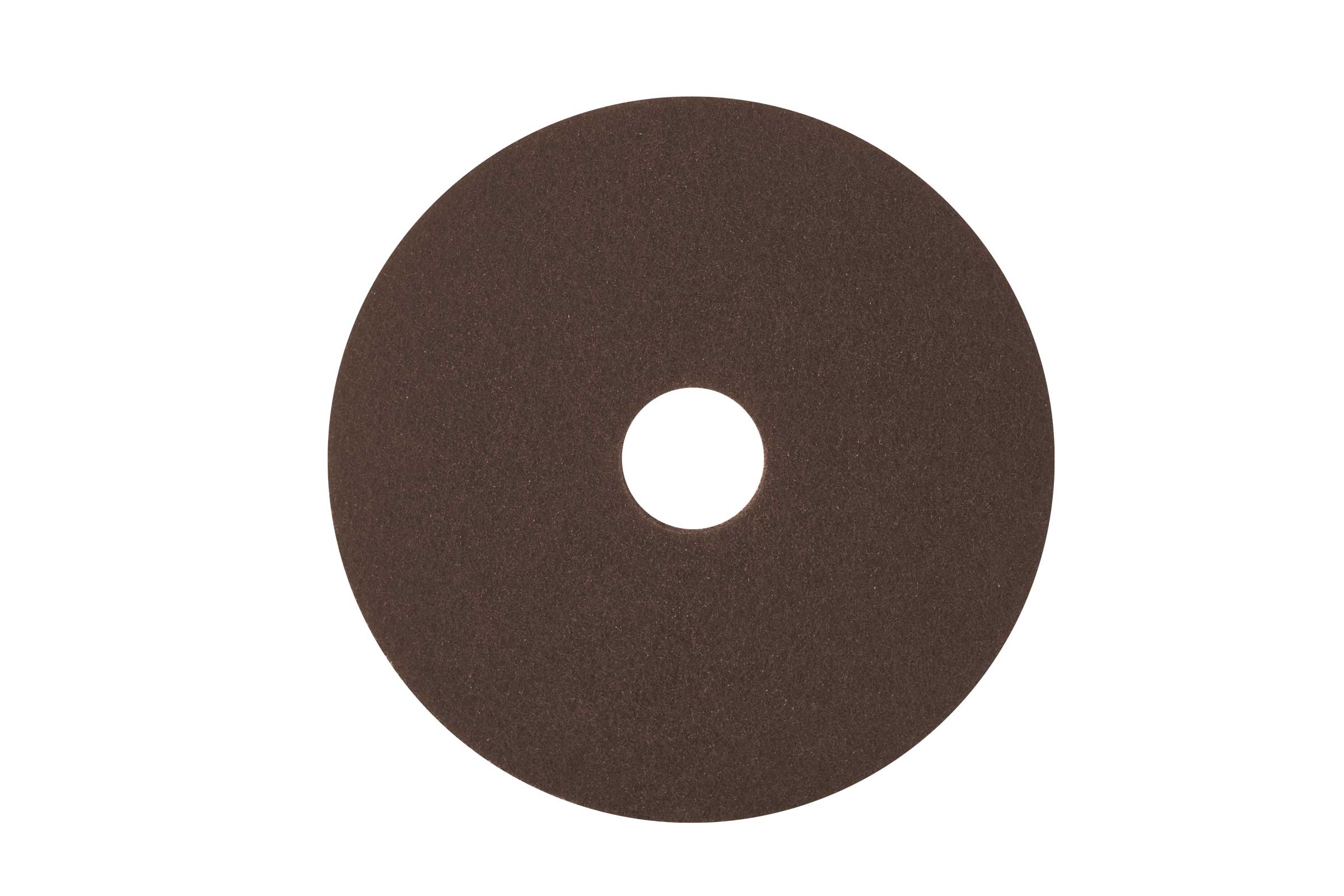

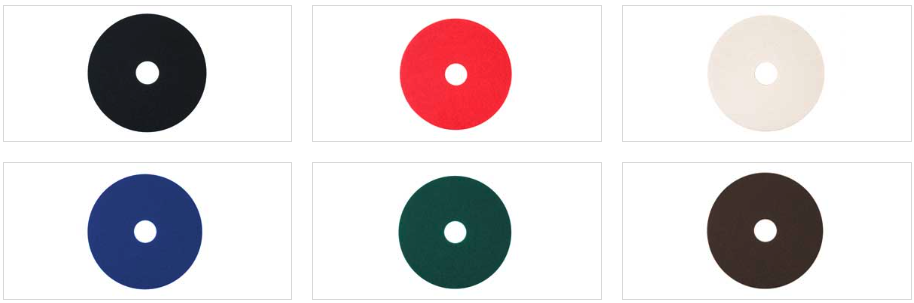

Different surface materials have different requirements for cleaning tools. For example, soft surfaces that are easily damaged, such as wooden floors or coated metals, should use soft white sponge pads to avoid scratches; while hard surfaces that require heavy stain removal or polishing, such as stone or old chemical industrial floors, are more suitable for black or red sponge pads, as they have higher wear resistance and grinding power.

2. Consider the type of cleaning task

The choice of sponge pad material will also vary depending on the cleaning task. Light cleaning and polishing can use softer white sponge pads, while heavy dirt removal or deep cleaning requires harder black sponge pads. Additionally, if wax removal or stone cleaning is required, chemical fiber sponge pads with added polishing materials can be chosen.

3. Machine type and weight

When using mechanical cleaning equipment, the choice of sponge pads should also be adjusted according to the weight and type of the equipment. Light single-disc machines are suitable for soft pads, while heavy grinding machines may require harder pads to provide sufficient support. This ensures both cleaning effectiveness and prevents machine damage due to overly soft pads.

4. Environmental requirements and safety factors

When selecting sponge pads, it is also necessary to consider whether they are suitable for specific environmental requirements. For example, in food preparation areas, materials that meet food safety standards may be needed to ensure no harmful substances remain. At the same time, for flammable environments, sponge pad materials with flame-retardant properties should be chosen.

5. Cost and service life considerations

When purchasing sponge pads, not only should the initial cost be considered, but also the service life and replacement frequency should be assessed. More durable sponge pads, although with a higher initial investment, may be more cost-effective in the long run. Additionally, the ease of maintenance and cleaning, as well as any necessary accompanying cleaning agents or equipment, should be considered.

6. Environmental factors

With the increasing awareness of environmental protection, choosing environmentally friendly, biodegradable, or reusable sponge pad materials is also an important factor to consider. This not only helps reduce environmental pollution but also enhances the corporate social responsibility image.

7. Testing and experimentation

Before making a final decision, it is possible to verify the actual effect of the sponge pad through sample testing. The effects in practical operation are often more accurate than theoretical choices, which can effectively avoid the secondary purchase costs due to improper material selection.

Color Classification and Uses

Color Classification and Uses

The Private Labeling Cooperati

The Private Labeling Cooperati

The Advantages and Precautions

The Advantages and Precautions

How to Choose the Material of

How to Choose the Material of