The Advantages and Precautions of Sponge Cloth OEM Services

In the consumer goods market, sponge cloth, as an essential tool for household and industrial cleaning, has always had a stable demand. With consumers' increasing demands for personalization and functionality, OEM (Original Equipment Manufacturing) of sponge cloth has become an effective way for brands and companies to meet market demands. Here are some advantages of sponge cloth OEM and considerations when choosing an OEM service.

Advantages of Sponge Cloth OEM

1. Flexible Production: OEM production can flexibly adjust the scale of production according to market demand without the need for huge investments to establish one's own production line, which is especially suitable for new or small-scale brands.

2. Professional Production: OEM factories usually have professional production technology and equipment, which can ensure the quality and stability of the products, meeting different customers' requirements for product quality.

3. Cost-Effective: Compared with building one's own production line, OEM production can significantly reduce production costs, allowing brand owners to focus more on product development and market marketing.

4. Quick Response to Market: OEM production has the ability to quickly respond to market changes, adjust production plans in a short time, and quickly meet new market demands.

5. Customized Services: OEM factories can provide customized services, including color, size, material, etc., to meet the diverse needs of different customers.

Considerations When Choosing Sponge Cloth OEM

1. Choose a Reputable OEM Factory: Ensure that the OEM factory has good production qualifications and market reputation to avoid choosing manufacturers with quality problems or those who do not keep their credit.

2. Clarify Product Quality Standards: Clearly communicate the product quality standards with the OEM factory, including material, size, durability, etc., and require the OEM factory to produce according to these standards.

3. Inspect Production Capacity: Visit the OEM factory to inspect its production capacity and technical level, ensuring it has enough capacity to complete orders on time.

4. Sign a Contract to Protect Rights and Interests: Sign a detailed contract specifying production quality, delivery time, intellectual property protection, and other terms to prevent disputes.

5. Continuous Supervision and Evaluation: Regularly supervise and evaluate the production situation and product quality of the OEM factory to ensure product quality is stable and meets expectations.

In summary, sponge cloth OEM provides brand owners with an efficient and economical product production method, but it is necessary to be cautious when choosing an OEM service to ensure that the products meet quality standards and consumer demands. By cooperating with professional and reliable OEM factories, brand owners can better expand the market and improve competitiveness.

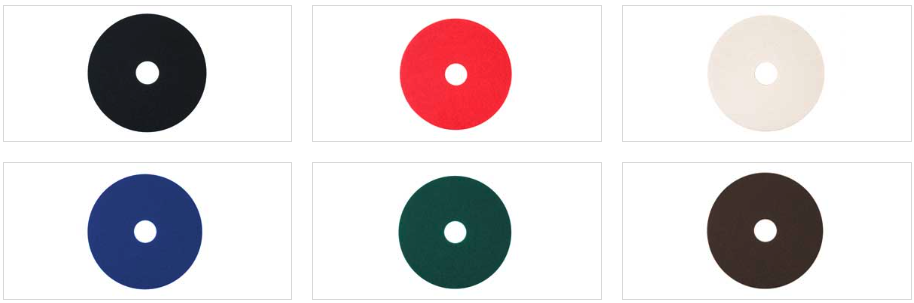

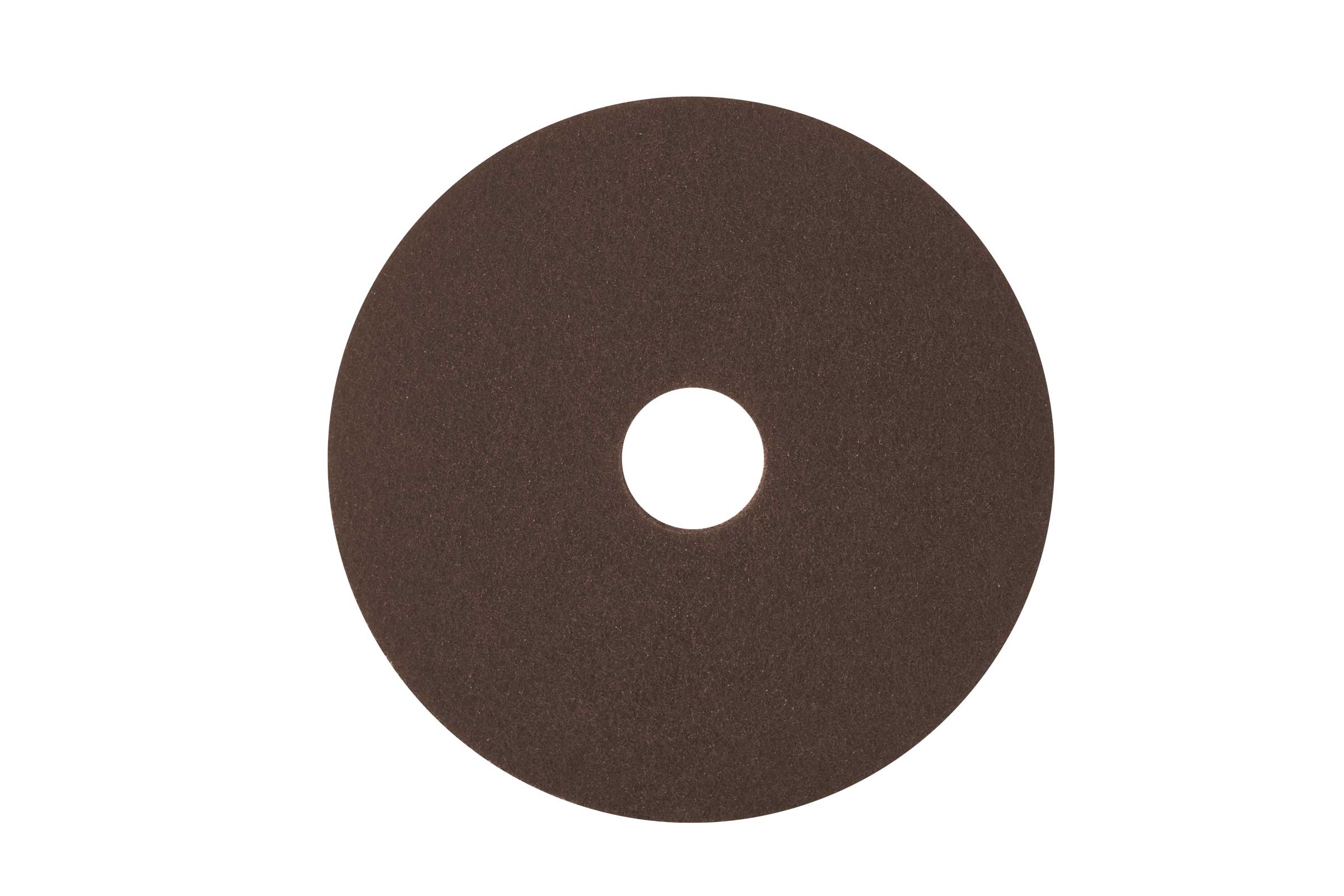

Color Classification and Uses

Color Classification and Uses

The Private Labeling Cooperati

The Private Labeling Cooperati

The Advantages and Precautions

The Advantages and Precautions

How to Choose the Material of

How to Choose the Material of